Precise measurement technology is the foundation for safe, efficient, and high-quality manufacturing.

With state-of-the-art optical and tactile measurement methods, we capture components either contactlessly or through direct contact — accurately, reliably, and reproducibly.

Our measurement solutions help you maintain quality standards, optimize manufacturing processes, and detect errors at an early stage.

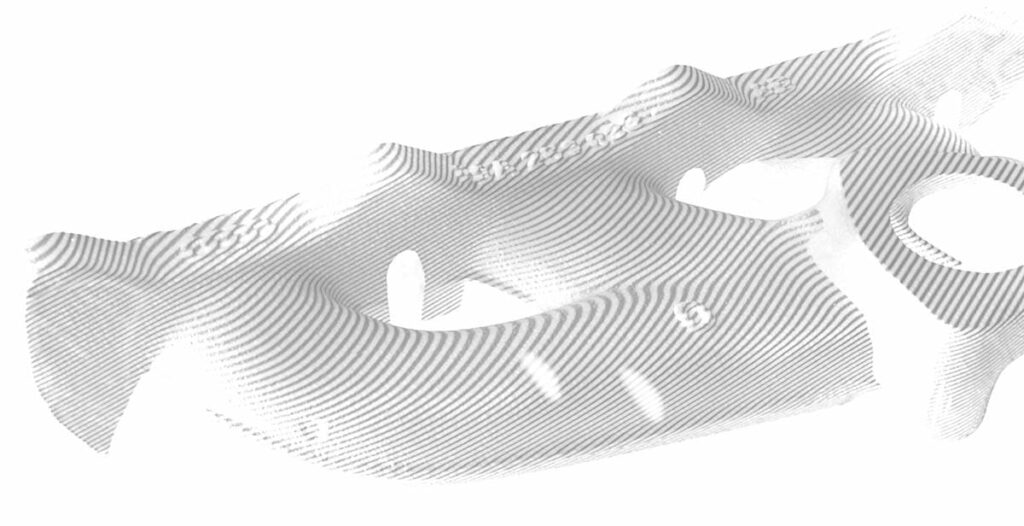

Our optical methods enable fast, high-resolution, and contactless measurement of complex geometries. Whether 2D or 3D analysis — we provide precise results even for delicate or hard-to-reach components. Ideal for series inspections, surface analyses, and form and position checks.

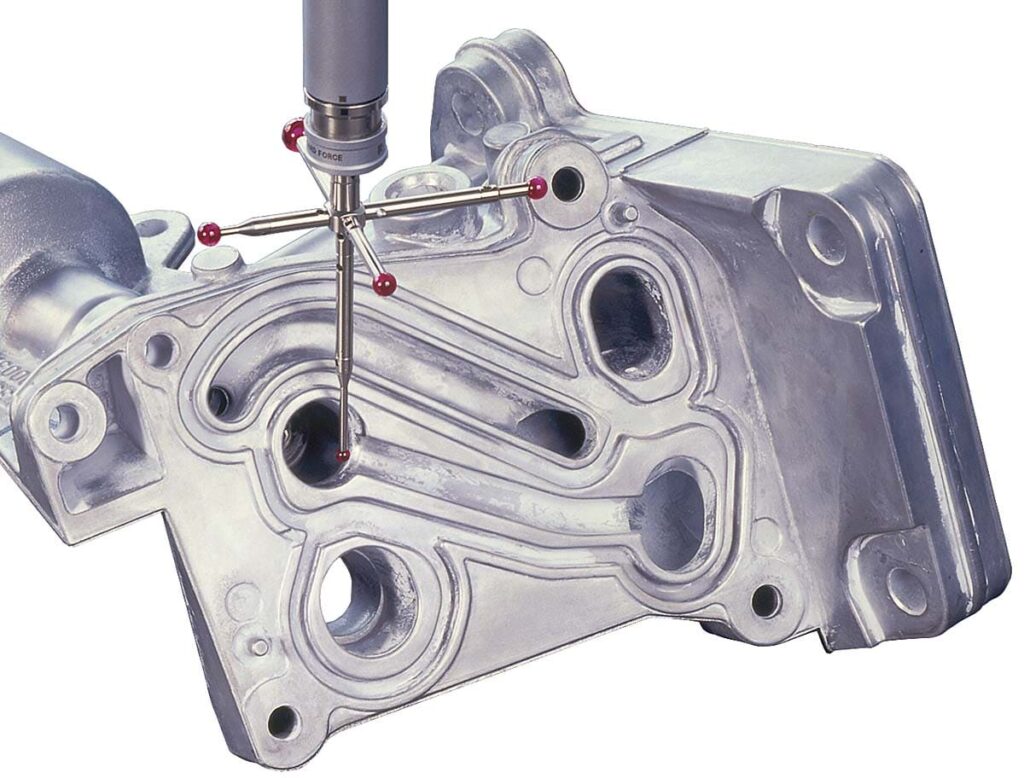

With our tactile measuring systems, we capture dimensional accuracy and geometric features with the highest precision. Due to the direct contact with the component, these methods are particularly well suited for precision measurements, initial sampling, and detailed quality inspections. Perfect for mechanically stressed components and tight tolerance requirements.

We combine state-of-the-art technology with expert knowledge — delivering reliable measurement reports, transparent evaluations, and certified quality. Our processes are standards-compliant, traceable, and fully documented. You receive clear results that support confident decision-making.