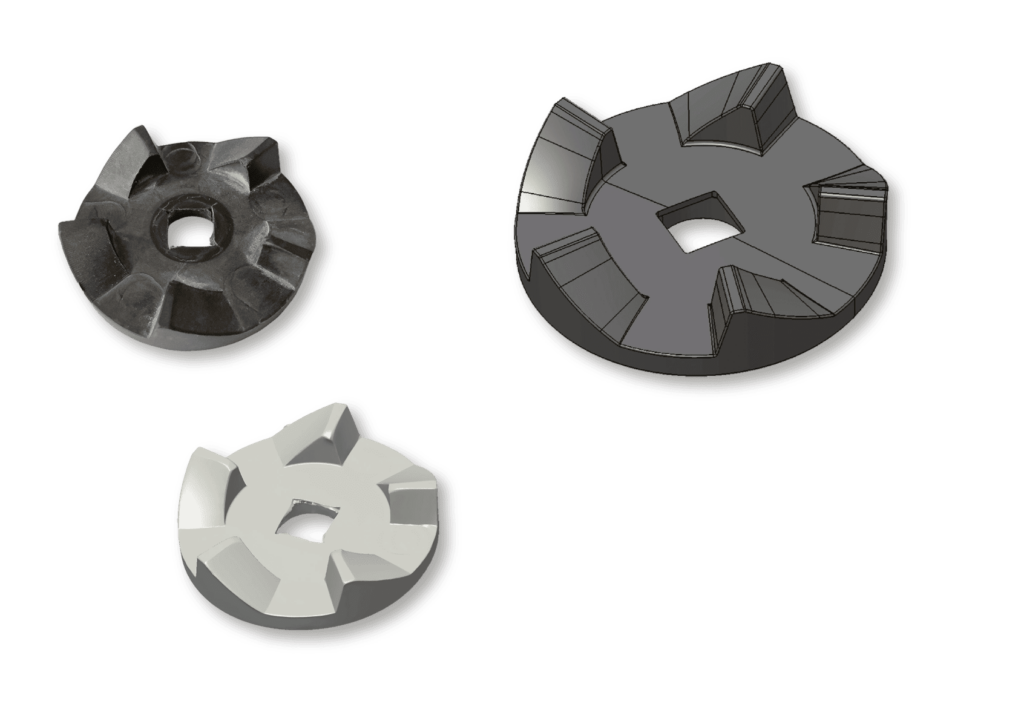

With modern reverse engineering, we turn existing components back into complete digital models.

Using optical and tactile measurement methods, we capture every detail — from simple geometries to complex freeform surfaces.

The collected data is then precisely converted into CAD models suitable for reproduction, optimization, or documentation.

This creates reliable digital replicas, even when no drawings or technical documentation are available anymore.

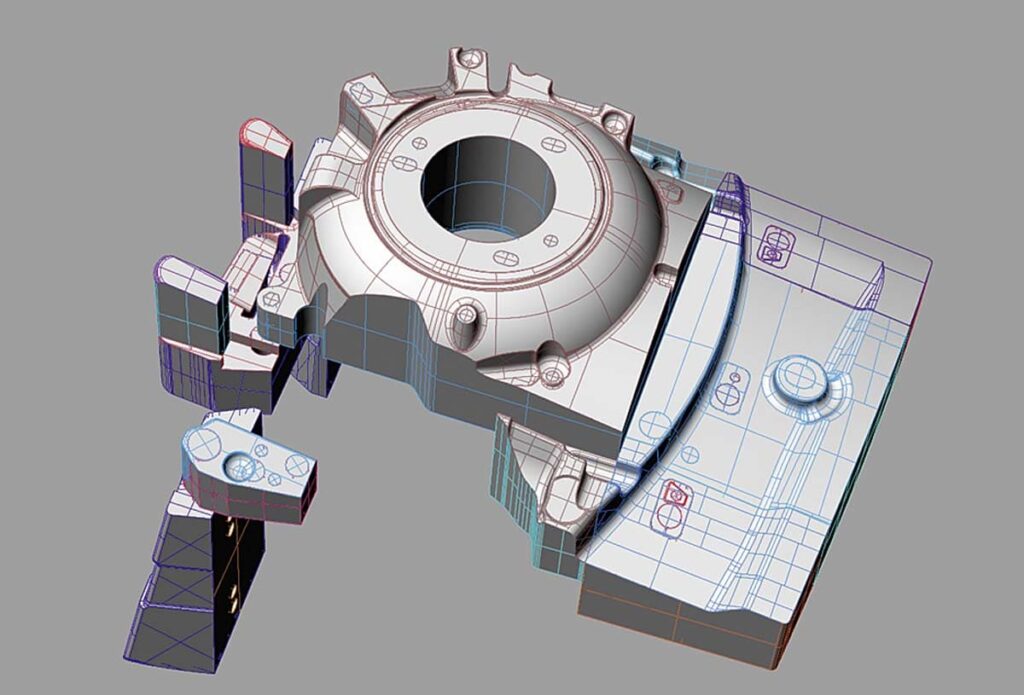

Using highly precise optical and tactile measurement methods, we capture components completely and with great detail. Even complex geometries, wear areas, or hard-to-reach sections are reproduced digitally with exact accuracy.

From the measurement data, we create clean, standards-compliant CAD models. Whether simple geometry or complex freeform surfaces — we reconstruct the component so it can be immediately reused or reproduced.

Reverse engineering not only makes reproduction possible, but also improves components. We analyze critical areas, optimize geometries, and prepare models for modern manufacturing processes.